Ameloot Group

Manipulating Porous Matter

Papers

Vapour-phase loading of ionic liquids into ZIFs @Inorg. Chem.!

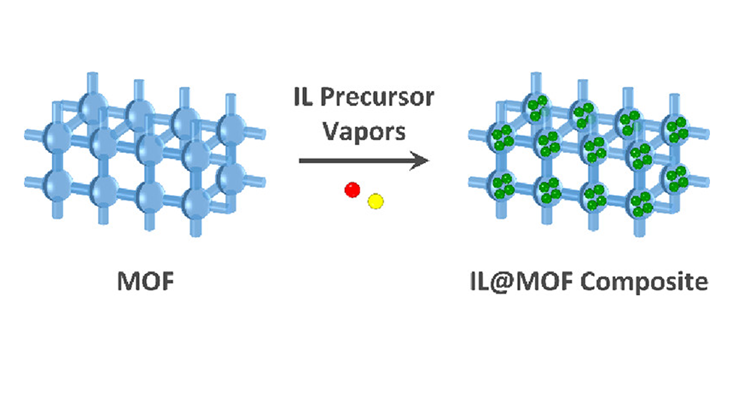

Composites formed by a metal–organic framework (MOF) and an ionic liquid (IL) are potentially interesting materials for applications ranging from gas separation to electrochemical devices. Consequently, there is a need for robust and low-cost preparation procedures that are compatible with the desired applications.

In this paper, we report a solvent-free, one-step, and vapor-based ship-in-bottle synthesis of the IL@MOF composite 1-butyl-3-methylimidazolium bromide@ZIF-8 in powder and thin film forms. In this approach, volatile IL precursors evaporate and subsequently adsorb and react within the MOF cages to form the IL.

More information here or on the Publication page of our website.

3D printing of autonomous concentration gradient generators @ Adv. Eng. Mater.!

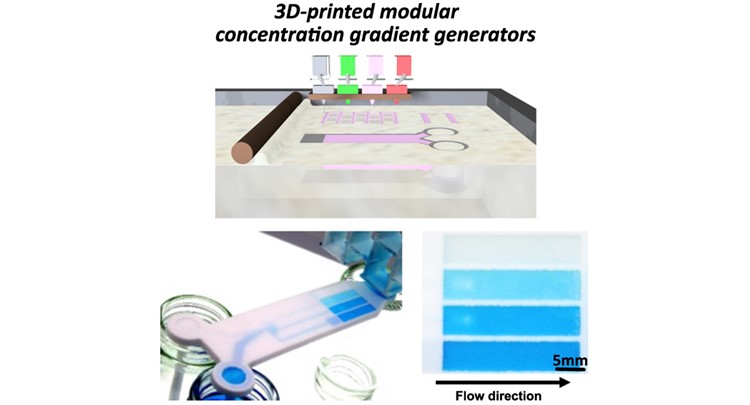

Concentration gradients feature widely in many biomedical processes (e.g., cell evolution, chemotaxis, personalized healthcare, and drug screening). The concentration gradient generators (CCGs) developed previously have used either static gradients or gradients maintained by a continuous co-flow. In this paper, we report a platform for the manufacture of autonomous CGGs through inkjet 3D printing on a powder bed.

The intrinsic microporosity of the 3D-printed devices produces efficient flow-independent gradient profiles. Computational fluid dynamics modeling of the porous devices reveals that mechanical dispersion, rather than diffusion or flow velocity, dominates the gradient formation. The gradients remain stable for up to 120 h with no need for external pumping systems and with minimal user intervention because on-device evaporation and capillary forces are the sole drivers. The ease of transitioning between a computer model of an object and its fabrication allows the rapid development of custom concentration gradients.

More information can be found here, or on the Publication page of our website.

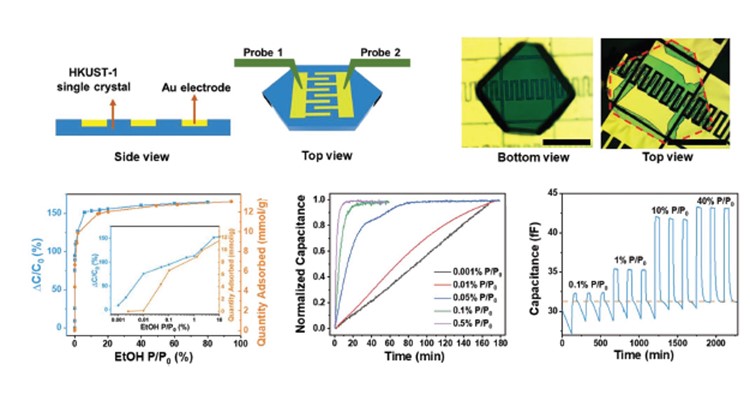

Our single-crystal capacitive sensors on the inside cover of Adv. Funct. Mat.!

A visualization of our paper 'Single-Crystal Capacitive Sensors with Micropatterned Electrodes via Space-Confined Growth of the Metal-Organic Framework HKUST-1' on the inside back cover of advanced functional materials!

Find the article here or on the publication page of the website.

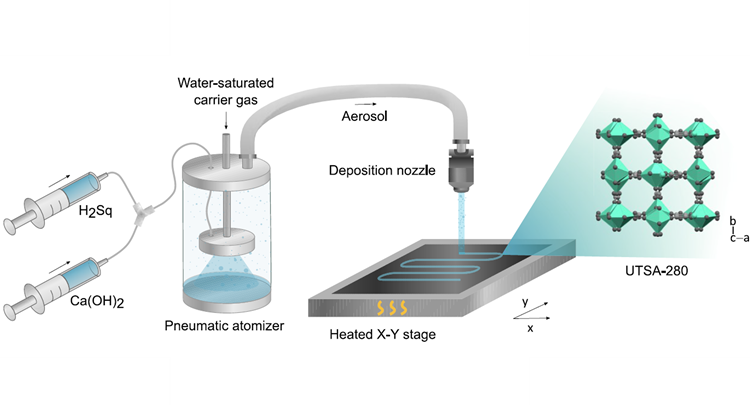

Aerosol Jet Printing of the ultramicroporous CaSq MOF @Chem. of Mat.!

Efficient methods to deposit thin layers of metal−organic frameworks (MOFs) are needed to integrate these microporous materials into microelectronics, sensing devices, and membranes. We report for the first time the direct aerosol jet printing of a MOF material. The ultramicroporous MOF [Ca(C4O4) (H2O)] (UTSA-280) was deposited from an aqueous precursor solution. In addition to blanket coatings, aerosol jet printing provides direct access to patterned coatings with a resolution of 100 μm via a digital, maskless approach. Moreover, by enabling spatial control over the layer thickness via the number of passes of the nozzle, this direct-write approach presents a more accessible alternative to advanced patterning techniques such as grayscale lithography.

More information can be found here, or on the Publication page of our website.

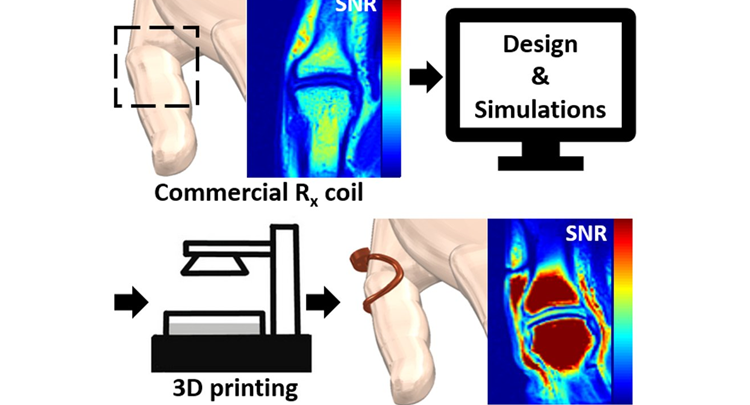

Additive Manufacturing of Subject-Conformal Receive Coils for MRI @Adv. Mat. Tech.!

High signal-to-noise (SNR)ratio is crucial to obtaining high-quality magnetic resonance images. However, a poor fit of fixed-size radiofrequency coils to the subject often limits the SNR both in research and clinical magnetic resonance imaging (MRI) practice. Therefore, there is an urgent need to fabricate RF coils that exhibit a close geometrical fit (or are subject conformal) to the to-be-imaged region.

In this report, a range of 3D printing methods is proposed for producing such conformal coils and overcoming constraints in geometrical complexity, production time, and cost. Laser powder bed fusion and stereolithography-based methods are explored. The fully digital workflow allows for the seamless integration of electromagnetic simulations of geometrically complex coils, resulting in rapid design iterations. SNR gains up to 68% are observed for single 3D-printed subject-conformal coils compared to a state-of-the-art commercially available (nonconformal) coil array. In addition to tests on phantoms, a conformal 3D-printed coil is used to image the metacarpophalangeal joint of the thumb from a volunteer on an MRI scanner to demonstrate the improved image quality.

More information can be found here, or on the Publication page of our website.

Single-crystal capacitive sensors of HKUST-1 @ Adv. Funct. Mat.!

The polyhedral shape and fragile nature of single crystals of metal–organic frameworks (MOFs) hinder their processing using standard microfabrication techniques. As a result, the fabrication of surface patterns and microelectrodes on MOF single crystals is challenging, which limits both the direct electrical interrogation of crystals in research and their integration into optical and electrical devices.

In this report, a new strategy to readily fabricate surface-embossed micropatterns and surface-embedded gold electrodes on MOF single crystals using a space-confined, one-step solvothermal synthesis is demonstrated. This method is based on the confined growth of the MOF crystal around prefabricated metal patterns with different adhesion strengths to the growth surface, producing features as small as 5 µm.

As a proof of concept, micropatterns are created on flat single crystals of the MOF HKUST-1, exhibiting the function as a diffraction grating. Additionally, a single-crystal HKUST-1 capacitive gas sensor with surface-embedded electrodes that serves as a stable platform for the investigation of ethanol diffusion in the MOF pores is fabricated.

More information can be found here, or on the Publication page of our website.

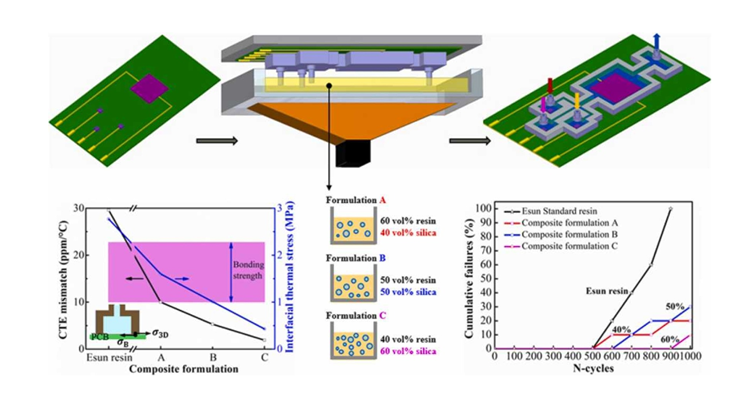

Photocurable resin-silica composites for 3D printing microfluidic components onto PCBs @Materials Today Comm.!

Fabricating microfluidics directly onto a printed circuit board (PCB) is a promising method to produce integrated systems. We applied stereolithography (SLA) to 3D print microfluidic components directly onto PCBs. Current SLA resins suffer from significant thermal expansion, which leads to adhesion issues during temperature cycling. In this paper, we report the development of photocurable composites with a low coefficient of thermal expansion (low-CTE composites) to address this bonding issue by minimizing the interfacial thermal stress. The resulting low-CTE resin-silica composites robustly bond to PCBs and can be used for fabricating PCB-based microfluidics in chemical engineering or thermal management (e.g., chemical reaction, 3D packaging, or heat removal devices).

More information can be found here, or on the Publication page of our website.

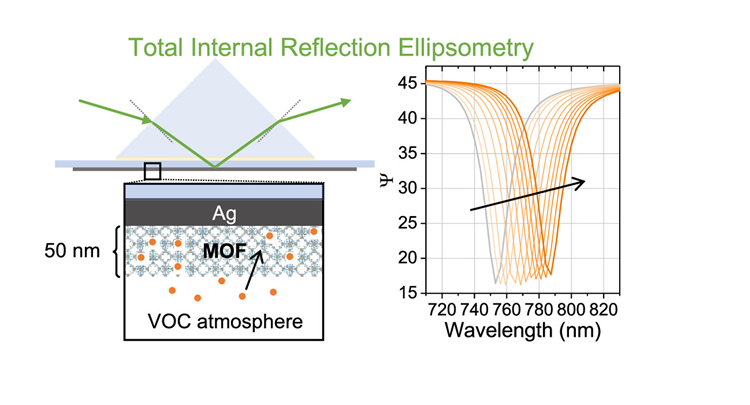

Ppm detection of VOCs via SPPs and MOFs @ACS Appl. Nano. Mat.!

Metal–organic frameworks (MOFs) are promising materials to realize chemical sensors. However, achieving high sensitivities requires the reproducible deposition of well-defined MOF films and their integration with a suitable sensor design.

In this work, we report the sensitive detection of volatile organic compounds (VOCs) by transducing the adsorption in zeolitic imidazolate framework 8 (ZIF-8) thin films, prepared by chemical vapor deposition, into surface plasmon polariton shifts measured via total internal reflection ellipsometry. SPP resonances tunable over the entire Vis–NIR range and as sharp as 14 nm are obtained for optimized synthesis conditions. Record-breaking shifts stronger than 150 nm upon methanol uptake and a limit of detection below 1 ppm are observed.

The paper can be accessed here or on the Publications page of our website.

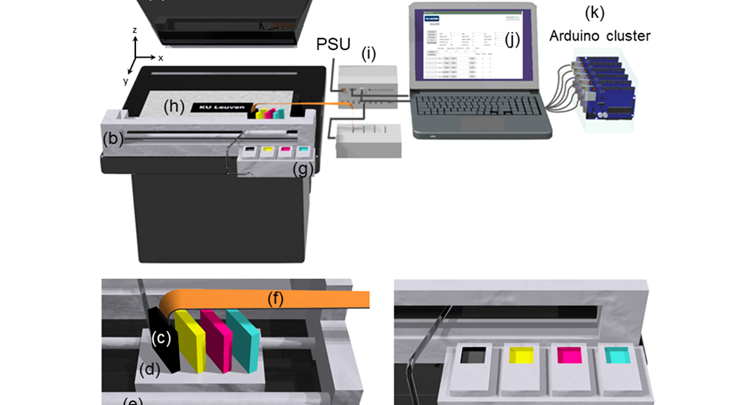

Custom binder-jetting 3D printer @Review of Scientific Instruments!

The limited control over the printing process in commercial powder bed 3D printers hinders the exploration of novel materials and applications. In this study, we report a custom binder-jetting 3D printer. The resulting fine-grained control over the printing process enables features such as voxel-based control over the printed ink volume, adaptive layer thickness, and selective multi-pass printing. Additionally, a protocol was developed to optimize the 3D printing process for new build materials and binders, in which resolution tests were used as a guideline for improving the dimensional accuracy.

The paper can be accessed here, or on the Publication page.

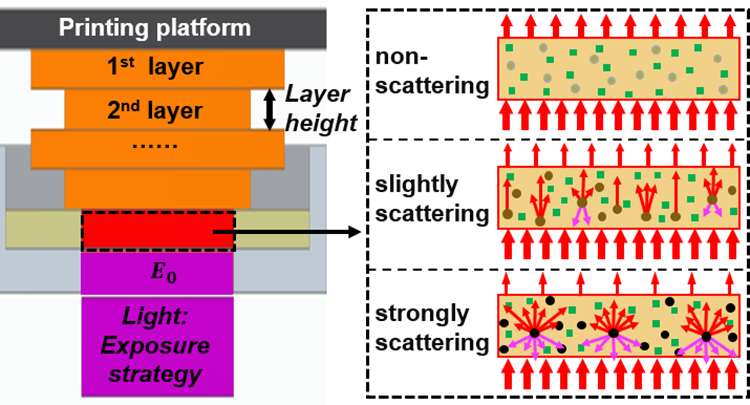

Scattering model for composite stereolithography @ ACS Applied polymer materials!

Fillers are used to modify the properties of photoresins used in stereolithography (SLA). The resulting composite formulations tend to have a decreasing cure depth for increasing particle loadings due to light scattering. However, some composites show the opposite effect: the cure depth increases with the particle loading. This study provides insights into light scattering in the particle filled SLA resins to unify these seemingly contradictory observations.

A modified Lambert−Beer equation that considers both scattering and absorption was established to evaluate the findings and expand the understanding of scattering in these composite formulations. This unified working curve equation facilitates the further development of particle-matrix SLA resins.

The paper can be accessed here or on the Publications page of our website.