Ameloot Group

Manipulating Porous Matter

guanghai fei

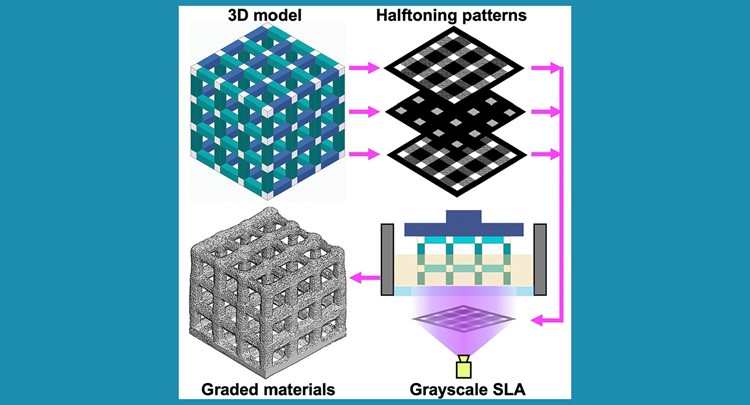

Digital halftoning for printer-independent SLA of functionally graded materials @Cell Rep. Phys. Sci.!

Grayscale masks have been applied in high-end stereolithography (SLA) 3D printers to spatially define the degree of photopolymerization and fabricate objects with graded properties. However, this approach cannot be applied in many commonly used projection SLA printers that can only handle 1-bit slices.

Based on dithering techniques and image-processing algorithms, we developed a digital halftoning approach to generate universally printable files consisting only of black and white pixels arranged to mimic the ‘‘true’’ grayscale levels. Using this approach, any SLA printer can be used to control the irradiation dose and the degree of photopolymerization in each printed layer. As proof of concept, we report various objects with graded properties using different commercial printers. This universal fabrication strategy will open a new window for engineers and scientists to explore grayscale SLA prints.

More information can be found here, or on the publication page.

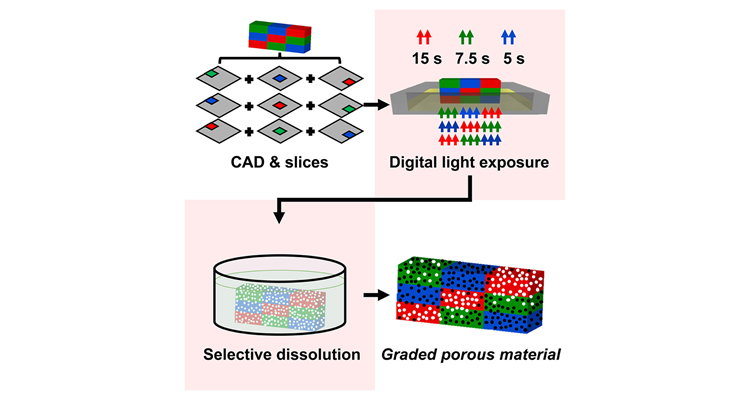

SLA 3D printing of graded porous materials @Cell Reports Physical Science!

Graded porous materials (GPMs) with fine pore sizes (<50 μm) and gradient porosity are used in diverse fields such as biomedical implants, sensors, and soft robotics. Stereolithography (SLA) 3D printing has created new possibilities for fabricating intricate porous materials due to its high speed and excellent resolution. Nevertheless, for many commonly used low-cost SLA printers, the traditional SLA process is not ideally suited to print GPMs since only a single material feedstock is used for the entire print.

In this paper, we demonstrate how this limitation can be overcome by using a composite feedstock consisting of a photoresin and a polymeric filler in combination with voxel-level digital control over the light exposure. Based on this strategy, spatial control over the porosity, mechanical properties, and swelling behavior within the SLA prints is achieved. We expect that this scalable fabrication strategy will contribute to a variety of applications that require GPMs.

More information can be found here, or on the Publication page.

Guanghai successfully defends his Ph.D.!

After successfully completing the public defense of his thesis, Guanghai was awarded his Ph.D.! His Ph.D. research focused on stereolithographic additive manufacturing for microfluidic device fabrication.

Congratulations Dr. Fei!

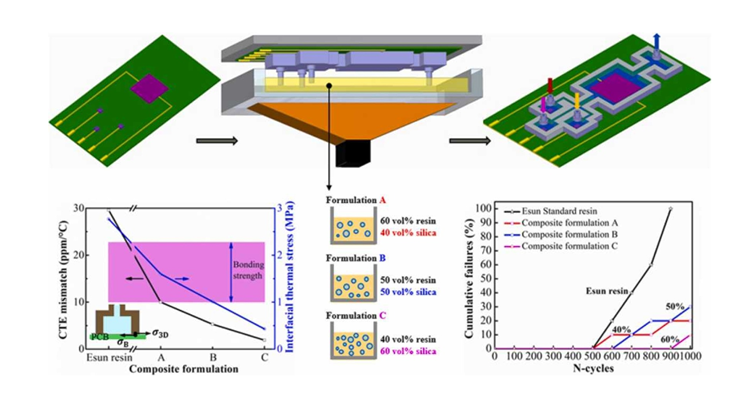

Photocurable resin-silica composites for 3D printing microfluidic components onto PCBs @Materials Today Comm.!

Fabricating microfluidics directly onto a printed circuit board (PCB) is a promising method to produce integrated systems. We applied stereolithography (SLA) to 3D print microfluidic components directly onto PCBs. Current SLA resins suffer from significant thermal expansion, which leads to adhesion issues during temperature cycling. In this paper, we report the development of photocurable composites with a low coefficient of thermal expansion (low-CTE composites) to address this bonding issue by minimizing the interfacial thermal stress. The resulting low-CTE resin-silica composites robustly bond to PCBs and can be used for fabricating PCB-based microfluidics in chemical engineering or thermal management (e.g., chemical reaction, 3D packaging, or heat removal devices).

More information can be found here, or on the Publication page of our website.