Ameloot Group

Manipulating Porous Matter

Vapor-Phase Processing of MOFs @Acc. Chem. Res!

Vapor-Phase Processing of MOFs @Acc. Chem. Res!

MOFs have shown disruptive potential in adsorption, catalysis, separation, etc. For many of these applications, MOFs are synthesized solvothermally as bulk powders and subsequently shaped as pellets or extrudates. Other applications, such as membrane separations and (opto)electronics, require the implementation of MOFs as (patterned) thin films. Most thin-film formation methods are adapted from liquid-phase synthesis protocols. Precursor transport and nucleation are difficult to control in these cases, often leading to particle formation in solution. Moreover, the use of solvents gives rise to environmental and safety challenges, incompatibility issues with some substrates, and corrosion issues in the case of dissolved metal salts. In contrast, vapor-phase processing methods have the merits of environmental friendliness, control over thickness and conformality, scalability in production, and high compatibility with other workflows.

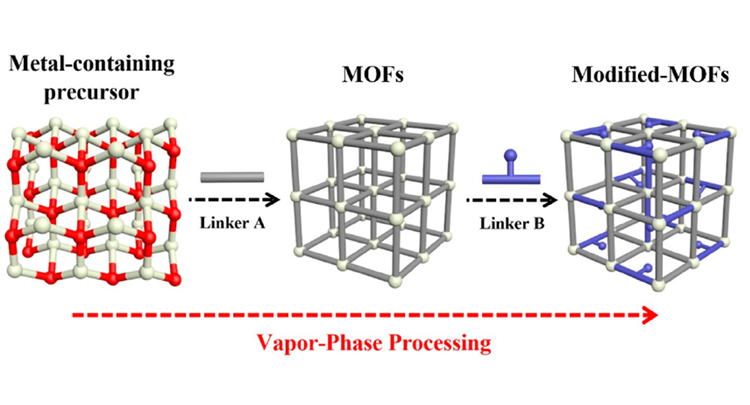

In this article, we report some of our efforts and related studies in the development and application of vapor-phase processing of crystalline MOF materials. We first highlight the advances and mechanisms in the vapor-phase deposition of MOFs. Second, four vapor-phase postsynthetic functionalization methods are summarized: linker exchange, guest loading, linker grafting, and metalation. Thirdly, since vapor-phase processing methods enable the integration of MOF film deposition into a (micro)fabrication workflow, they facilitate a range of applications with improved performance (low-k dielectrics, sensors, membrane separations, etc.). Finally, a discussion is provided on the limitations, challenges, and further opportunities for MOF-VPP.

The article can be found here or on the publication page of our website.