Ameloot Group

Manipulating Porous Matter

Chem Soc review paper on 3D printing

Chem Soc review paper on 3D printing

Our review paper on 3D printing in chemical engineering and catalytic technology was accepted in Chemical Society Reviews.

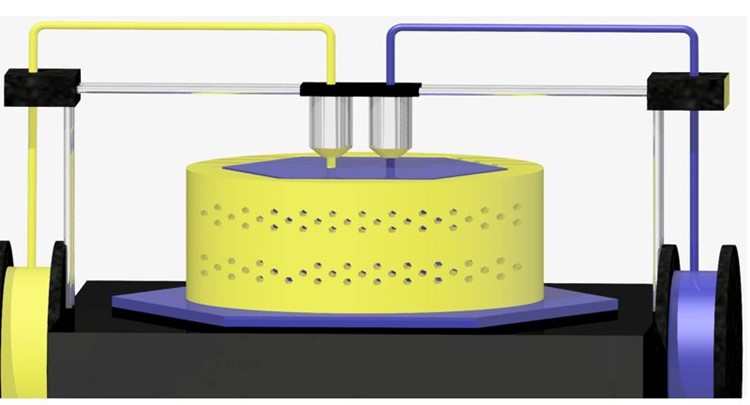

In the field of catalytic technology and chemical engineering the impact of 3D printing, is steadily increasing thanks to a rapidly decreasing equipment threshold. Although still in an early stage, the rapid and seamless transition between digital data and physical objects enabled by these fabrication tools will benefit both research and manufacture of reactors and structured catalysts. 3D printing closes the gap between theory and experiment, by enabling accurate fabrication of geometries optimized through computational fluid dynamics and the experimental evaluation of their properties. Our review highlights the research using 3D printing and computational modeling as digital tools for the design and fabrication of reactors and structured catalysts. The goal of this contribution is to stimulate interactions at the crossroads of chemistry and materials science on the one hand and digital fabrication and computational modeling on the other.