Ameloot Group

Manipulating Porous Matter

Additive Manufacturing of Subject-Conformal Receive Coils for MRI @Adv. Mat. Tech.!

Additive Manufacturing of Subject-Conformal Receive Coils for MRI @Adv. Mat. Tech.!

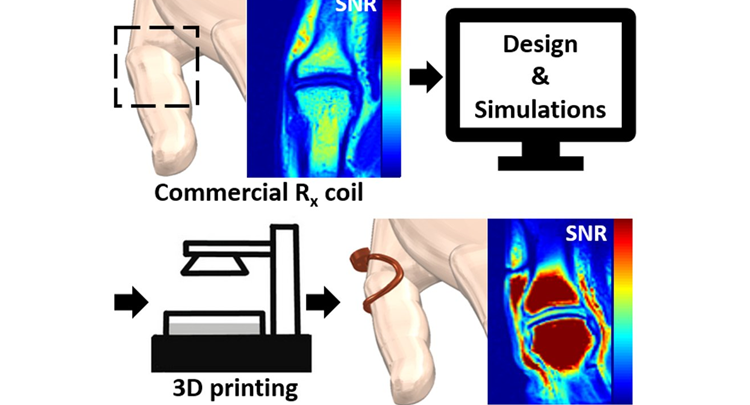

High signal-to-noise (SNR)ratio is crucial to obtaining high-quality magnetic resonance images. However, a poor fit of fixed-size radiofrequency coils to the subject often limits the SNR both in research and clinical magnetic resonance imaging (MRI) practice. Therefore, there is an urgent need to fabricate RF coils that exhibit a close geometrical fit (or are subject conformal) to the to-be-imaged region.

In this report, a range of 3D printing methods is proposed for producing such conformal coils and overcoming constraints in geometrical complexity, production time, and cost. Laser powder bed fusion and stereolithography-based methods are explored. The fully digital workflow allows for the seamless integration of electromagnetic simulations of geometrically complex coils, resulting in rapid design iterations. SNR gains up to 68% are observed for single 3D-printed subject-conformal coils compared to a state-of-the-art commercially available (nonconformal) coil array. In addition to tests on phantoms, a conformal 3D-printed coil is used to image the metacarpophalangeal joint of the thumb from a volunteer on an MRI scanner to demonstrate the improved image quality.

More information can be found here, or on the Publication page of our website.