Ameloot Group

Manipulating Porous Matter

3D printing of ferromagnetic passive shims for field shaping in magnetic resonance imaging

3D printing of ferromagnetic passive shims for field shaping in magnetic resonance imaging

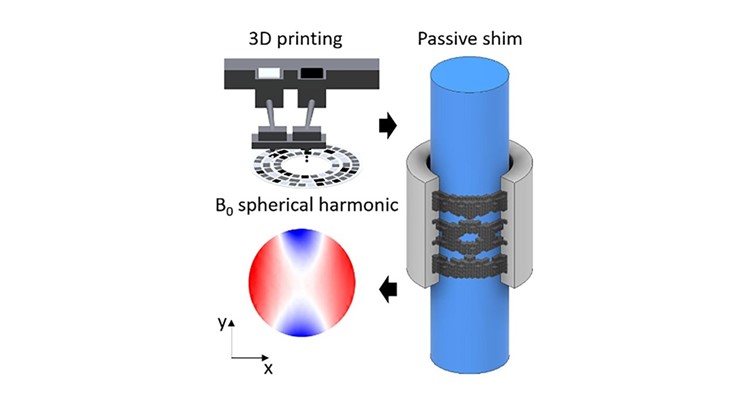

Magnetic Resonance Imaging (MRI) often encounters image quality degradation due to magnetic field inhomogeneities. Conventional passive shimming techniques involve the manual placement of discrete magnetic materials, imposing limitations on correcting complex inhomogeneities. To overcome this, we propose a novel 3D printing method utilizing binder jetting technology to enable precise deposition of a continuous range of concentrations of ferromagnetic ink. This approach grants complete control of the magnitude of the magnetic moment within the passive shim enabling tailored corrections of B0 field inhomogeneities. By optimizing the magnetic field distribution using linear programming and an in-house written Computer-Aided Design (CAD) generation software, we printed shims with promising results in generating low spherical harmonic corrections.

Experimental evaluations demonstrate feasibility of these 3D printed passive shims to induce target magnetic fields corresponding to second-order spherical harmonic, as evidenced by acquired B0 maps. The electrically insulating properties of the printed shims eliminate the risk of eddy currents and heating, thus ensuring safety. The dimensional fabrication accuracy of the printed shims surpasses previous methods, enabling more precise and localized correction of subject-specific inhomogeneities. The findings highlight the potential of binder-jetted 3D printed passive shims in MRI shimming as a versatile and efficient solution for fabricating passive shims, with the potential to enhance the quality of MRI imaging while also being applicable to other types of Magnetic Resonance systems.

Check out a visualization of this article on JMR cover!

More information can be found here, or on our publication page.